Integrating ERP and TMS

Companies can deliver products and materials faster and at a lower cost through the integration of TMS within Enterprise Resource Planning (ERP) systems.

The ERP system maintains data on products and business partners as materials and customers, respectively. This data then needs to be transferred to the TMS.

To connect the standalone TMS within the ERP system, companies often use middleware — a software layer that facilitates the exchange of data between the two systems.

Integrating TMS functionalities directly into ERP becomes more efficient with cloud-based solutions, such as cloud ERP development and customization.

With direct integration, both systems synchronize the product master data and harmonize the master data for key business objects, like organizational structures, business partners, and transportation networks.

After integration, companies often gain better visibility into their transportation processes, enabling real-time decision-making.

We offer custom ERP/TMS integration services to connect procurement, order management, inventory, finance, and transportation functions to eliminate manual data entry, reduce errors, and enhance real-time visibility across operations. Get in touch.

Transportation Management Process Flow

Manufacturers, distributors, e-commerce entities, and logistics service providers, in the movement of goods, heavily depend on TMS software to handle transportation data and processes.

Transportation requirements for Ordering and Delivery

Sales Orders

Sales Orders, Purchase Orders, and Deliveries specify transportation requirements. The Transport Management system can automatically extract information from these documents.

Whether through a sales representative or an online portal connected to the ERP system, a sales order is automatically generated when a customer places an order. It details the Sold-To Party (customer), Ship-To Party (delivery address), ordered items, and Net Value. In turn, purchasing documents serve multiple purposes, such as procuring raw materials, obtaining vendor-consigned inventory, or subcontracting the production of a material. Delivery documents group items for one recipient.

A screenshot of an example Sales Order Interface showcasing the Sold-To and Ship-To Party Details along with Net Value for streamlined transportation planning

The Ship-To Party's address in the screenshot matches the Sold-To Party's, indicating delivery to the buyer's address. Matching fields are common when billing and shipping addresses are the same.

Upon the creation of the sales order, it is integrated with the Transport Management system, facilitating the automated transfer of order details for delivery planning.

Changes to the transportation status of orders in the TMS are instantly reflected in real-time.

As the order progresses through different stages, various departments within the company update the system:

The logistics department adjusts transportation details, such as scheduling, pick-up times, and carrier information.

The system receives updates from the warehouse team when they pick, pack, and get items ready to be shipped.

The transportation team or external carriers may enter the status of the shipment, indicating its current location in transit or if it has been successfully delivered.

Some updates are automated via system integration with external partners or Internet of Things (IoT) devices. For example, tracking systems in trucks or ships can send live location data to the system, keeping the transportation status up to date.

Screenshot of the 'Status In Tendering', indicating the process of selecting subcontractors via a tender is currently underway

The TMS uses a document flow to keep track and manage the lifecycle of a freight unit, which is a shipment planned as a single entity.

This includes all associated paperwork and electronic records from creation to delivery.

Screenshot of the Document Flow

There are three key components in the document flow:

'Outbound Delivery' refers to the dispatch of goods from a specific location.

'Sales Order' details the products, quantities, and agreed prices for the products or services.

'Freight Order' corresponds to the transportation request for the freight unit and includes details on routing, scheduling, and carrier information.

Forwarding Orders

Forwarding Orders are instructions used by shippers to provide Logistics Service Providers (LSPs) with shipment details. This includes the number of items, dimensions, weight, destination, and any special handling requirements.

These orders are particularly useful for individual shipments or when transportation requirements do not follow a regular schedule. They can be issued as needed.

Scheduling Agreements

Scheduling Agreements are long-term contracts that outline rules for regular deliveries such as quantity, timing, cost and other details. These agreements are used when a company requires regular delivery of the same items without the need to place a new order each time.

We had a positive experience with a US freight management companies. Their digital transformation included TMS solutions and API integrations to streamline operations, reduce errors, and enhance service delivery. For a practical example of how these principles were applied, check out the selected case study.

Capacity Management

Transportation capacity management is about planning logistics in advance, thereby securing better rates and avoiding premium charges for last-minute arrangements. It also guarantees that transportation is available during peak times.

Strategic Freight Procurement

Strategic freight procurement involves negotiating long-term contracts with carriers or LSPs for various freight services, including return freight, container provisioning, packaging, customs processing, and insurance.

Freight Agreement Documents

A freight agreement document details terms between a shipper and a carrier or logistics provider. The process includes updating current contracts and forming new ones. Within a TMS, users create these documents, specifying a responsible organizational unit and the associated carrier. Each agreement contains a calculation sheet for charges based on built-in rates.

In the example, an organizational unit with ID '50000206' refers to the internal department or division within the company that manages the freight agreement. A logistics service provider with ID '3200000046' is labeled as 'Foreign Vendor.'

The Basic Rate is a fixed cost for every shipment, covering overhead, like handling, administration, and basic operational fees.

Freight charges vary based on distance, weight, and transportation type. Shipment specifics affect charges.

By separating these two costs, a TMS can apply costs to a shipment more accurately.

LSPs handle numerous agreements with carriers. By analyzing historical data in TMS on capacities and costs in different aspects, they can identify the most cost-effective shipping methods. This helps them to decide whether to provide end-to-end transportation services or subcontract certain parts of the freight movement.

Establishing Key Performance Indicators (KPIs) enables LSPs to measure and assess the performance of their carriers. Identifying carriers that meet or exceed these KPIs ensures that LSPs work with efficient partners.

Sending RFQs through TMS helps select the best option. LSPs analyze carrier responses, either by charge type or through an optimizer-based comparison, considering constraints.

Freight Allocations

Allocations are reservations about shipping capacity with a carrier, such as a shipping company or a freight transporter. These agreements represent documented commitments that a specified amount of capacity is reserved for the shipper's use during a designated period. The purpose is to guarantee enough capacity for the shipper's goods on a carrier for a specific route and time.

In TMS, allocations can be based on time periods (weekly, monthly, quarterly, yearly) and the amount of space or weight capacity reserved.

Screenshot of the Freight Allocation schedule indicating specific carrier reservations and quarterly capacity buckets

In this example, 'freight allocation 2' is a specific allocation made for carrier '1000030' along trade lane '1000000000', from source location 'ZSVENDOR10' to destination 'ZSVENDOR1'. Four capacity-based buckets have been created for this allocation, each corresponding to a quarter within the validity period. Each bucket allows a maximum gross weight of 40 tons.

Strategic Freight Selling

The process begins when a shipper or customer shows interest by submitting a Request for Quotation (RFQ), which can be communicated through Electronic Data Interchange (EDI) transfer, email, or phone. For instance, a customer may make a spot booking or inquiry with an LSP agent.

Once the customer's interest is registered, a freight manager in the TMS analyzes their historical data to determine the best service offerings.

The next step is to create a forwarding agreement quotation within the TMS. This quotation includes multiple items with rates outlined in a charge calculation sheet. These rates are determined manually or with tools like the rate builder cockpit, using rate tables and scales.

The customer receives the completed quotation through EDI or email. It provides a detailed proposal with service and rate specifics.

A formal forwarding agreement is generated in the TMS once the customer accepts the quotation.

Freight Bookings

Freight bookings are the documents that reserve specific capacities with carriers. Based on strategic allocations and agreements, operational teams book capacity with carriers for specific shipments. Freight bookings specify the type and quantity of equipment (e.g., containers) and scheduling details.

Carriers and partners receive freight bookings and documents via Electronic Data Interchange (EDI).

Linking freight bookings to precursors and subsequent documents ensures traceable movements.

Using a dashboard enables transportation managers to monitor closely the performance of freight carriers against predefined targets. This section of the dashboard provides a visual comparison between the current load (the actual weight of goods being transported) and the target load (the planned weight) for each carrier.

Screenshot of a carrier performance dashboard displaying current load versus target load for Freight Bookings

For example, HD Busy Business and American Airlines Inc. have both reached 100% of their target load. Conversely, Aramex and Inter Transport GmbH have reached 0% of their targets, meaning no goods have been transported.

Transportation Planning

The aim is to optimize the loading of each vehicle for transportation, maximizing capacity to reduce fuel usage, minimize trips, and lower overall transportation expenses. To plan transportation efficiently, orders going to the same or nearby places are consolidated into fewer shipments.

Screenshot of a TMS Package Unit Interface indicating detailed cargo information for transportation planning

Using the Package Unit interface in the 'Cargo Information' and 'Required Capacity' sections, logistics companies can input specific details like cargo weight and volume.

A Gantt chart displays when resources area in use and when they are available. The map feature in the cockpit shows cargo routes and movements visually.

Freight Units

Companies in diverse industries face challenges in distributing products to multiple customers across regions with varying sizes, weights, and special requirements.

To manage this, they can use a TMS to consolidate orders into freight units based on criteria such as destination, product type, and delivery schedules.

Freight units are grouped by size and form, from a single pallet to a full truckload, container, or smaller package. These units remain stable throughout the transportation process, from origin to destination.

For example, by comparing automatically generated tables with known parameters, such as expected weight and volume ranges for products, the planner can ensure accuracy and make any necessary adjustments before incorporating the order into the planning workflow. Once the data is accurate, they can proceed with routing, scheduling pickups and deliveries, and allocating resources, such as assigning trucks and scheduling drivers.

If transportation demands or resources require adjustments, the company can choose to split or merge the freight units.

They can also use package simulation to calculate the ideal package size and quantity, minimizing wasted space and shipping costs. For orders with mixed products heading to the same destination, the company may create mixed packages to combine various products within a single package or pallet layer.

Freight Orders

Freight orders detail and authorize goods' movement. If these orders are not in place, it will be impossible to transport goods or make use of transportation units like containers.

The Package Unit is part of the freight order, grouping multiple items. It consolidates items after finalizing freight units and establishing a load plan.

In practice, when a logistics company has goods to transport, it can use the Package Unit interface to enter detailed data, such as the cargo's weight and volume, in the 'Cargo Information' and 'Required Capacity' sections.

The 'Maximum Utilization' metric shows the percentage of the transport unit's capacity occupied by the cargo.

Logistics personnel can input cargo origin and destination in 'Source' and 'Destination'.

The 'Transportation' section records the total distance and duration of the transportation, as well as the frequency of visits to specific locations.

Transportation Cockpit

The Transportation Cockpit within a TMS serves as a dashboard for transportation planners and dispatchers who are responsible for executing planned shipments and planning incoming orders.

TMS Transportation Cockpit screenshot depicting Freight Unit stages for execution and planning

The Freight Unit Stages area displays attributes of freight units from orders or deliveries ready for shipment. This includes information such as freight unit number, original order number, loading and unloading locations, requested pickup and delivery dates and times, service level agreements, weight, volume, and quantity. Planners can split or merge freight units, insert or merge stages, and create or remove capacity/freight documents.

Screenshot of a TMS Freight Orders/Freight Bookings Interface displaying detailed transportation planning and carrier assignment

The Freight Orders/Freight Bookings area encompasses details such as freight order or booking number, means of transport, assigned carrier, and subcontracting status. Planners can mass-update multiple freight orders or bookings, enhancing efficiency over editing them individually.

Canceling orders or bookings can remove freight units from the schedule if the transportation plan is no longer valid. This may require a re-plan.

This section allows for the selection of carriers based on priority, cost, allocation, and more. The tendering process is facilitated within this area, allowing communication with carriers to accept or reject tendering requests.

TMS Capacity Dashboard displaying various transport vehicles and their maximum carrying capacities

The Capacity dashboard displays an available means of transport, their carrying capacities, registration numbers, and other critical information. Planners can add a new means of transport.

For manual planning, the planner analyzes the volume of products to be shipped, considers delivery deadlines, and then selects the appropriate vehicle, carrier, and schedule. Planning each order individually is time-consuming for companies with high shipment volumes. The Vehicle Scheduling and Routing (VSR) optimizer module of the TMS can handle high shipment volumes automatically. All freight units with delivery times, costs, etc. can be inputted by the planner. The optimizer proposes the best transportation plan, considering cost and time, and provides an explanation.

TMS Vehicle Scheduling and Routing module interface for optimal transportation planning and vehicle allocation

For example, before incorporating the order into the planning workflow, the planner can compare the plan with known parameters, such as expected weight and volume ranges, and correct any anomalies. If the data is accurate, they can proceed with routing, scheduling pickups and deliveries, and allocating resources, such as assigning trucks and scheduling drivers.

Our logistics and transportation software development services provide custom solutions that effectively bridge any gaps between TMS and ERP functionalities, improving data flow and system synchronization. Get in touch to get the details.

Load Optimization

Load optimization improves the arrangement of goods in a truck or container to maximize efficiency and space utilization. It also minimizes disruptions when delivering to multiple stops.

Before departure, the TMS allows the company to check the load planning status, indicating whether goods are ready for loading or unloading at each stop.

The Load Planning process begins with defining a hierarchy in the freight order, typically involving a vehicle resource, and a package, followed by the product. The TMS displays the load plan status for package items directly in the freight order.

Dynamic Load Planning interface demonstrating the arrangement of goods for optimized space utilization in transport vehicles

During package building, the system evaluates the items within freight units to select suitable packaging options. It then creates package units considering the items' compatibility and packaging requirements.

Advanced 3D Load visualization showing the strategic placement of packages in a transport vehicle for efficient load distribution

With package information, the TMS analyzes dimensions of the packages and the transportation resource (e.g., truck, container) to develop a comprehensive load plan.

Packaging materials vary widely in size, shape, and capacity. To effectively use different packaging materials in conjunction, a hierarchical system should be established.

TMS display of unit measurements, showcasing the conversion between individual items and packaging materials

TMS overview of packaging conversion, indicating how multiple cartons are consolidated onto a single pallet for transport

According to the screenshot, a company determined that one carton can hold 200 units of the product. Then, 10 of these cartons can be securely and efficiently stacked onto a pallet. The pallet facilitates the transportation of the grouped cartons.

Once the goods are loaded optimally, the next step is to determine the most efficient transportation route. This is where the Distance and Duration Determination function comes into play. It leverages a third-party geographic information system (GIS) to calculate the shortest distance between locations, considering geo coordinates stored in the system.

Additionally, the service order manages services beyond transportation, such as customs clearance, container cleaning, and inspection of container seals.

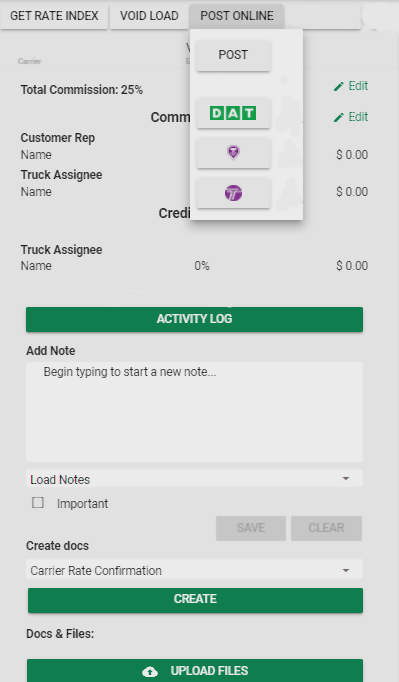

Carrier selection and subcontracting

Evaluating the organization's fleet and external shipping companies is part of carrier selection. Considerations include cost, service quality, reliability, coverage, and meeting shipping requirements. In this context, load boards facilitate efficient load matching for freight brokers, shippers, and carriers. Subcontractor selection involves assessing compliance with regulations, insurance coverage, and meeting obligations. The track record in on-time delivery, goods handling, and reliability are important factors.

Carrier Selection Constraints

TMS narrows carrier options based on constraints like hazardous materials and limited service areas.

Freight Tendering

After creating a freight order and selecting a carrier, the TMS uses tendering functionality. This involves communicating transportation requirements to potential carriers and receiving their responses. Tendering can be done via peer-to-peer methods, which may or may not require a response, or through broadcast methods, which accept either the first or the best offer depending on the situation.

TMS interface screenshot of peer-to-peer tendering with response required is selected

Tendering Analysis

The TMS provides tools like the Tendering Analysis dashboard to review and analyze tendering activities, including the cycle times of various carriers.

Dashboard view in a TMS showing tendering cycle times and carrier performance metrics

For instance, if Carrier GmbH consistently has the shortest tendering cycle time, it may be preferred for future shipments to enhance efficiency.

Manage Freight Agreement RFQ Masters

This functionality enables shippers and LSPs to secure optimal carrier partnerships and rates.

Interface of freight agreement RFQ masters in TMS, detailing status and deadlines for carrier bids

It involves sending detailed transportation requirements to potential carriers and evaluating their bids. Actions, such as accepting a freight RFQ without changes, proposing adjustments, or outright rejection, are supported based on negotiation outcomes.

TMS dashboard for transportation order management, displaying actionable items for freight RFQs and quotations

Transportation monitoring and execution

Completing freight activities includes scheduling vehicle dispatch, ensuring proper loading, and preparing necessary documentation. Real-time tracking with GPS and RFID allows companies and customers to know the exact location of a shipment. Communication between drivers, managers, and customers helps in sharing information about delays, or route changes. Real-time monitoring enables fast decision-making, such as changing the route or finding an alternative way to send the goods.

Transportation Monitoring

Transportation monitoring provides updates on the location and status of the freight. The dashboard may offer insights into carrier on-time performance, order status, delays, and unexpected events during transit.

Dashboard showing real-time transportation monitoring in TMS, with insights into order lifecycle, delays, and unexpected events in transit

Reporting and Analytics

The Freight Order Execution Dashboard allows for daily monitoring of data. It provides insights into shipment status, the number of orders in process, and any delays. For example, if a manager notices that a specific carrier consistently performs poorly during peak periods, they can choose not to assign critical shipments to that carrier to prevent potential delays.

TMS event timeline displaying milestones from 'Ready for Loading' to 'Departure', with 52 In Process freight orders and 0 delays in transit

Detailed view of a freight settlement document, capturing financial and organizational data for transportation management accounting

Managers can analyze KPIs, such as weight, volume, and the number of shipments on a weekly, monthly, or custom date range basis. This analysis can be done for carriers, shippers, or the final destinations of shipments.

Dashboard snapshot displaying key performance metrics for freight orders, providing real-time insights into transportation efficiency

The Freight Order Execution dashboard includes features like the Tendering Peer-to-Peer Cycle Analysis.

Managers can also make daily decisions about workload distribution among carriers to ensure a fair distribution of orders.

TMS dashboard with analysis of weight, volume, carrier performance, and network efficiency

Documentation Management

Creating and handling waybills and bills of lading is part of Documentation Management. A bill of lading is a receipt and legal document for claiming shipped goods. LSPs act as intermediaries between shippers and carriers and may issue their own bills of lading. Shippers must provide a bill of lading to the consignee when transporting goods. However, a waybill serves the purpose of tracking and includes a list of the goods being transported.

Event Management

The role of Event Management is to track and document significant moments during the lifecycle of a freight order. It captures the location and timing of key milestones from the origin to the destination.

Analysis of carrier response times in tendering, illustrating peer-to-peer efficiency and carrier metric

Planned events are scheduled steps in the shipment's journey, like departure from a warehouse or arrival at the destination. These events are based on the logistics plan. Let's say, if a shipment is set to leave a distribution center at 9:00 AM on a Tuesday, this departure is a planned event that falls under the scope of Event Management.

Unplanned events, however, are incidents that happen without notice and are not part of the original plan. Some examples of these obstacles are traffic delays caused by congestion or accidents, breakdowns of transportation vehicles, and unforeseen weather that make travel difficult. These events demand immediate attention and may require adjustments to the shipping plan to minimize delays or damages. For instance, if a truck breaks down, the logistics team must respond quickly to fix the vehicle or find an alternative transport method to keep the shipment on schedule.

Freight charge management and settlement

This process manages transportation costs, including maintaining contracts with transportation service providers to handling the invoices and payments for freight orders. Carriers will invoice the shipper after providing transportation services. Verifying invoices is necessary to ensure they match contracted rates and accurately reflect provided services. Resolving disputes over invoices is also part of freight charge management, which can involve issues with the billed amount, discrepancies in weight or classification of shipped items, or services that were billed but not provided. Payments can be processed once invoices are verified.

When a company establishes freight agreements with carriers, it sets rates for various services. There are two types of agreements available: forwarding agreements, which require the customer to pay charges, and freight agreements, which require the carrier to pay charges.

Departments decide which type to choose - sales for forwarding agreements, purchasing for freight agreements.

To calculate charges for freight orders, the system retrieves rates from a specific line item within an agreement.

Transportation Charge Calculation Sheet

The Transportation Charge Calculation Sheet (TCCS) is essential for determining the charges to be paid to freight vendors. It records charge types and their corresponding rate tables. The TCCS focuses on an item table, with each item representing a specific charge.

Rate tables can be maintained manually or through Microsoft Excel integration and must be linked to their respective calculation sheet.

Freight Settlement Document

The charge management process starts with creating a freight settlement document.

This document triggers a series of events, leading to the generation of a service purchase order, goods receipt, and service entry sheet. The subsequent posting of accruals, invoice verification, and self-billing processes heavily rely on these documents.

The supplier's invoice is compiled from freight documents like a freight order, freight booking, or service order. The freight settlement document collects all invoicing data from these freight documents. It may also include additional services like customs brokerage, container cleaning, or fumigation, expanding its scope beyond transportation services.

After the invoice undergoes processing and verification, the freight settlement document displays the verified invoice amount, marking the culmination of the charge management process.

Verified invoice amount of $60.00 on freight settlement document

In the screenshot, the "Verified Invoice Amount" field shows $60.00. This means that after verification, the invoice for $60.00 was correct and should be paid to the service provider according to the terms in the document.

Components of Enterprise Transportation Management System

General Master Data and Organizational Structure

Organizational master data refers to the core information that defines an organization's structure.

Legal Boundaries specify company names, registered jurisdictions, and regulatory frameworks. For transportation, it helps manage legal responsibilities in different territories, ensuring compliance with shipping regulations.

Geographic Boundaries outline the locations of headquarters, regional offices, warehouses, and distribution centers. This information aids in managing logistics, routes, and shipping across different locations. Additionally, it ensures the fulfillment of tax requirements and adherence to legal regulations in the local area.

Organizational Boundaries define the internal structure of an organization, such as departments, business units, and teams, along with their specific functions and relationships. Managing the flow of goods, information, and decisions relies heavily on this structure. It helps assign responsibilities from ordering and inventory management to shipping and customer service.

Product Master Data

The concept of "product master data" refers to the details about tangible items, including consumer goods, components, and raw materials that a shipper handles. It also encompasses the services provided by logistics service providers, like transportation or warehousing.

Product master data comprises various attributes and details of each product or service, ranging from basic information like product names, descriptions, and pricing to specific details such as dimensions, weight, material compositions, and other defining characteristics.

The product master may also include the information about transportation materials and equipment used in the shipping process, such as pallets, pallet cages, and cardboard boxes.

Dangerous Goods

Dangerous goods can be harmful due to their chemical or physical properties. Transporting them requires careful handling and adherence to strict regulations.

An ERP system can recognize and flag products classified as dangerous goods. Without accurate recognition of these goods, it would be impossible to apply necessary precautions for handling and transport.

The system can verify that dangerous goods meet safety standards for transportation by checking packaging, labeling, and handling instructions. It follows local and international regulations for shipping dangerous goods.

A logistics manager can manually initiate the check process in the ERP system or the system can automatically conduct these checks.

Business Partners

In transportation execution, a business partner usually means customers and vendors who a company has business contacts with. The information of these business partners needs to be combined and stored in one location in the company's system.

Transportation Network

The transportation network is responsible for moving goods and freight between locations.

Locations are the precise geographic points where goods are either picked up or delivered. These can be warehouses, factories, retail stores, ports, or any physical place involved in the supply chain.

Transportation Zones group locations together to simplify and manage planning, routing, pricing, and service level agreements. Zones are defined based on factors like geographical proximity, shipping volumes, delivery times, or operational convenience.

Transshipment Locations are designed for transferring goods between different types oftransport. Examples include ports where goods are moved from ships to trucks or trains, rail terminals where goods are shifted from trains to trucks for last-mile delivery, and major logistics hubs where goods might be consolidated for further transportation or distribution.

Transportation Lanes are paths between locations, such as from a manufacturing plant to a distribution center. They are specific to modes of transport like road, rail, air, or sea, and are operated by carriers.

Trade Lanes, on the other hand, are lanes known for their efficiency and lower costs. Companies often make agreements with carriers for a certain amount of cargo space within these trade lanes to ensure availability. This allows companies to plan their supply chain operations effectively, as they know that space has been allocated for their goods on specific routes.

Routes, in turn, are detailed paths within transportation lanes, including all intermediate stops and transshipment points. They define exact sequences of transportation lanes that a shipment will pass through.

Transportation Schedules

The transportation schedule contains a set of departure rules for different locations.

An example interface for an ocean carrier

A standard port sequence is a predetermined order in which a vessel (cargo ship, container ship, cruise ship, etc.) visits ports on its route.

SHORE (which may be a manufacturing site), and PLATFORM (which could be a refinery) are the names or codes for the locations. SHORE is the first location and PLATFORM is the second, indicated by the order of '10' and '20'.

Location Type Codes categorize the type of location (port, terminal, station, etc.).

Location Address provides the specific address.

2,735.98 KM specifies the distance between the SHORE and PLATFORM locations.

Carrier ZB08ER1 is the code for the carrier company or vessel responsible for transportation between these two locations.

A departure rule for a voyage states the guidelines for when a vessel is scheduled to leave a port.

It includes the route from SHORE to PLATFORM.

Departure Rule indicates the start date for when the rule becomes active and the end date.

The checkboxes represent the weekdays when trips are scheduled (Monday to Friday).

This schedule ensures a dedicated transport service is available five days a week between SHORE and PLATFORM. It helps prevent delays in the supply chain and allows for advance planning of production and shipping resources, improving efficiency and predictability in the company's operations.

The ERP system has a 'Standard Port Sequence' section for defining the static aspects of a maritime route, including specific locations and their visitation order. The 'Voyages' section focuses on scheduling and operating routes over time.

Transportation Resources

Vehicles represent the different modes of transport available, such as trucks, trains, ships, and planes, that physically move goods from one place to another.

Transportation Unit Capacity refers to how much each vehicle can carry or transport. It helps in planning efficient loading of goods.

Calendar Resources denote the operating hours of locations like warehouses, ports, and distribution centers for scheduling pickups, deliveries, and transfers to ensure timely operations.

Reach out to us for a smooth TMS implementation that will optimize logistics operations, lower expenses, and enhance service quality.

Dzmitry Garbar

•

19

min read

We have been working for over 10 years and they have become our long-term technology partner. Any software development, programming, or design needs we have had, Belitsoft company has always been able to handle this for us.

Founder from ZensAI (Microsoft)/ formerly Elearningforce